SEISMIC DESIGNS

More Robust Overhead Hardware System Designs Reduce Seismic and Wind Damage

Utility companies are paying out millions of dollars for destruction caused by high winds and earthquakes. Have you ever wondered how many of these losses are preventable by better structural design?

Let's look at field data from Southern California Edison.

A lineman identified a problem pertaining to the common transformer cluster bracket. Below are four pictures to illustrate a problem with excessive stress on utility poles caused by design inadequacies in existing transformer cluster brackets.

Lineman taking pictures from a bucket reported gaps between the top of the heavy framing member and the pole of approximately ½ inch.

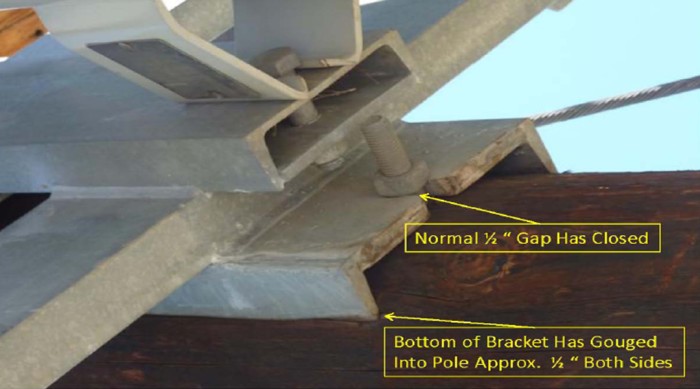

Lineman taking pictures from a bucket reported the normal ½ inch gap between the bottom bolt and the top of the slot in the frame had closed, and the bottom of the bracket had gouged into the pole approximately 3/8 to ½ inch.

Existing Heavy Transformer Bracket Design — Splitting of the pole was observed, potentially related to overstressing of the bolts.

Existing Heavy Transformer Bracket Design — Perspective of areas of stress described in previous slides. The photo has been rotated from vertical to horizontal for easier viewing.

Transformer platforms can be designed to better withstand wind loads and seismic loads and better protect your investment in transformers. Working with Southern California Edison, INWESCO has helped redesign a platform to better withstand wind and seismic loads. The two pictures below contrast the design differences.

Current Platform Design

New Platform Design

INWESCO Provides Design and Fabrication Support for New Products to

Withstand Seismic Loading and Wind Loads for Overhead Hardware Systems

Working together with Southern California Edison, INWESCO designed, engineered, and manufactured a new transformer cluster bracket to withstand high winds and seismic activity.

The bolting pattern has been updated by adding more bolts to crucial contact points as well as adding stabilizing arms that can adjust to the size of the pole and keep the bracket from side to side movement during high winds or rocking during seismic activity.

Let’s look at these products more closely:

35A316 Transformer Cluster Bracket

Transformer Platforms