MAINTENANCE TIPS FOR FRAMES & COVERS

DOORS AND COVERS NEED MAINTENANCE

Scroll Down for Lubrication / Cleaning Examples

FRAMES AND COVERS ARE NOT MAINTENANCE-FREE.

Time flies. Frames and covers are sitting out in the weather and while the metals are durable, the bolts securing the cover, the moving parts, and the frame channels need maintenance for ease of entry.

MAINTENANCE WILL PREVENT SEIZING ISSUES WITH BOLTS AND HINGES.

When covers come from the INWESCO factory, the bolts securing the cover and the hinges are properly maintained. Once the bolts securing the cover are removed, an application of an anti-seize compound or a simple lubricant is needed to prevent corrosion, and to assist in removal of bolts later.

GALVANIC REACTIONS CAN ALSO CREATE CORROSION AND MAINTENANCE ISSUES.

Dissimilar metals in contact, like stainless steel bolts securing standard steel covers, or stainless steel bolts securing aluminum covers, can create galvanic action. Galvanic action can create a current and a molecular bonding between the metals — corrosion — that will make removal more difficult later.

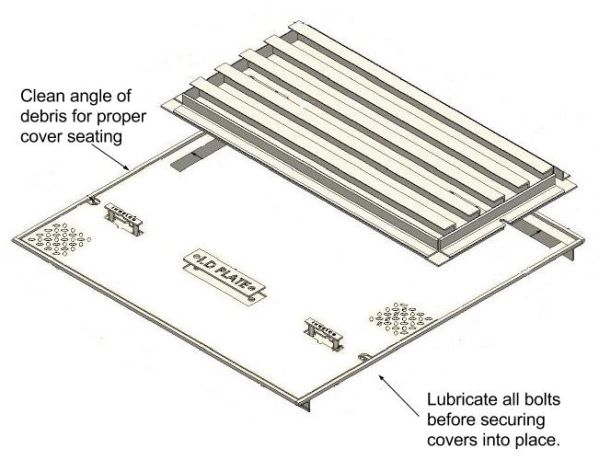

AN APPLICATION OF AN ANTI-SEIZE COMPOUND OR A LUBRICANT MAKES THE DIFFERENCE.

Anti-seize or a lubricant creates a film to prevent the galvanic current that creates the corrosion. When the entry is complete and the cover is being re-secured, personnel need to:

- treat the bolts securing the cover with an anti-seize compound or a simple lubricant.

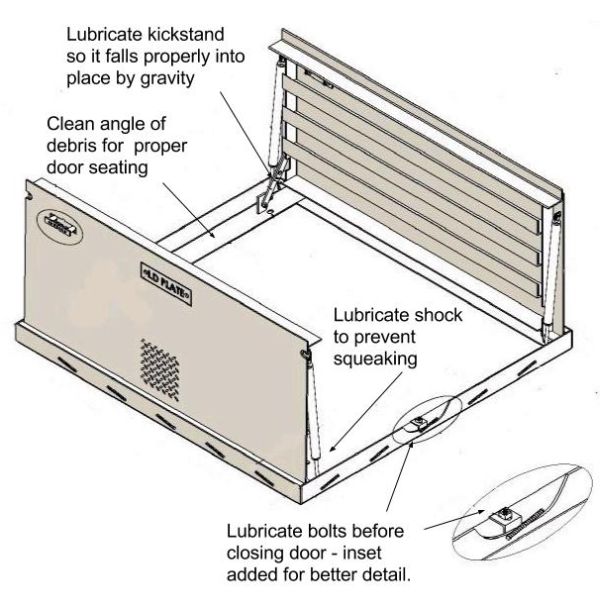

- make sure the hinges are properly lubricated. Stiff hinges can increase the lifting load as well as give a foothold to corrosion and build-up. You don’t want squeaky hinges, so lubrication here can be helpful.

THE KICKSTAND ALSO NEEDS ATTENTION.

The kickstand needs lubrication at connection points and at kickstand rotation points. The kickstand area can also suffer from the intrusion of debris that can impact how well it works. The kickstand needs to swing freely so that as the door opens, gravity lets the kickstand hinge swing into a locked position.

MECHANICAL ASSIST LIFT ASSEMBLIES CAN ALSO USE LUBRICATION ON THE SHAFTS.

These can dry out and squeak loudly. A little lubrication here can help keep down annoying metal on metal squeaks, plus insure ease of entry by proper operation of the lift-assist mechanisms.

BOLTS ALSO NEED TO BE PERIODICALLY TIGHTENED.

Repeated heavy traffic can jar loose the bolts. Doors clanking with traffic on them is a sure sign that bolts need tightening.

DEBRIS AND DIRT CAN CREATE PROPER CLOSING AND CORRECT SEATING ISSUES OF DOORS AND COVERS.

We need to remove debris and dirt from metal channels which can create compaction issues and create proper seating issues. Debris and dirt can blow in, or be dragged into the cover channels and create a compaction problem, and create issues with proper fitting of frames and covers. Frames and covers are tight and built to close tolerances. Debris can and will interfere with ease of use and proper operation of the covers.

BE PREPARED TO CLEAN OUT THE DEBRIS WHICH BLOWS INTO THE TRACKS OF THE COVER.

A small vacuum or a properly sized scoop and brush will make this clean-up easy and prevent problems before debris builds up to a maintenance issue.

GENERAL USE GUIDELINES TO INSURE BEST PERFORMANCE:

DON’T THROW COVER DOORS OPEN.

The shocks are quite sturdy, but slamming the doors open puts excessive pressure on the fasteners holding the shocks and can break fasteners.

The doors are heavy and can deliver a highly leveraged impulse load to the assist-shock assembly. These items will last indefinitely under normal wear and tear, but excess force added can break assist-lift attachments.